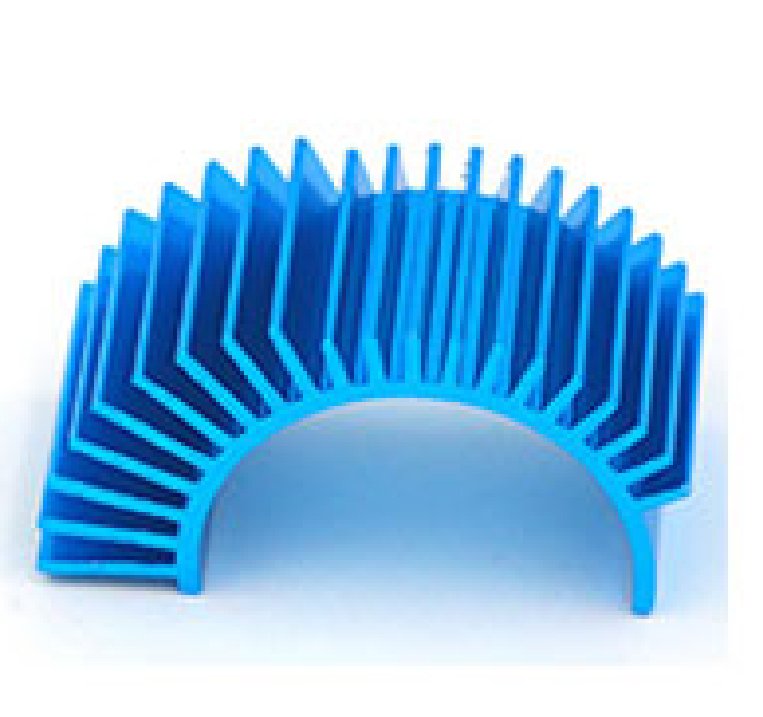

Motor Heat Sink

Motor Heat Sink

A motor heatsink is a cooling device designed to dissipate heat generated by electric motors. It prevents overheating, maintaining motor performance and longevity, especially in applications like electric vehicles and industrial machinery.

Being an expert in motor heatsink manufacturing, Tone offers a range of standard heatsinks for motors in various specifications. We proGET A QUOTE vide a variety of manufacturing techniques for these heatsinks.

Part of Our Products

Tone's team assists throughout your motor heatsink manufacturing journey, covering design, prototyping, material sampling, manufacturing, and production stages.

| Material | Aluminum, Copper |

| Temper | T3-T8 |

| Shapes | Based on your requirements. |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| MOQ | Low MOQ |

| Application | pico projector, electronic refrigerator, red wine cooler, LASER TV, LCD TV, LED panel, Sound, Air condition, induction cooker,stage light, high bay light, downlight, street light, automobile lamp, computer mainboard, PC, IPC, Server, PCTV, Router, Power supply (CPU cooler, VGA cooler, Cooling fan) |

| Deep process | CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sandblasted, Powder coating, Silver plating, Brushed, Painted, PVDF, etc. |

| Certificate | CE/SGS/ISO/Rohs |

| Service | 1. Free sample, Free design. 2. OEM/ODM available. 3. Custom-made request. 4. New design solution suggestion. |

● Efficient Cooling in Vertical Orientation

● Aesthetic Appeal

● Versatility

● Improved Structural Integrity

Searching for a top-notch motor heatsink for your business or project? Count on Tone as your ideal choice. We're your ultimate partner for successful motor heatsink projects.

Our Workshop

send 3D and CAD drawing, confirm production details

confirm the order and start to make samples.

Customization Process

surface treatment confirmation.

send samples to confirm quality and product details

we send the quotation to your for review.

after sample is confirmed, we will start mass production

The Process of Heat Sink Production

Our Packaging

1.What is a motor heatsink?

A motor heatsink is a cooling component designed to dissipate heat generated by electric motors during operation. It helps maintain optimal temperatures and prevents overheating.

2.Why do I need a motor heatsink?

Electric motors generate heat due to electrical resistance and mechanical friction. Heatsinks prevent overheating, enhancing motor performance, and extending its lifespan.

3.Which motors benefit from heatsinks?

Heatsinks are beneficial for various electric motors, including those in electric vehicles, industrial machinery, robotics, and drones, where consistent performance is critical.

4.How does a motor heatsink work?

Motor heatsinks increase the surface area for heat dissipation. They absorb heat from the motor and release it into the surrounding air, effectively preventing temperature buildup.

5.Are motor heatsinks one-size-fits-all?

No, motor heatsinks come in various sizes and designs to fit different motor types and applications. Proper sizing ensures optimal heat dissipation.

6.Can I retrofit a heatsink onto an existing motor?

Yes, heatsinks can often be added to existing motors, provided there is space and proper mounting options. It's essential to choose a compatible heatsink and ensure proper installation.

7.How do I choose the right motor heatsink?

Consider the motor's specifications, power requirements, available space, and operating conditions. Consulting with experts can help you select the best-suited heatsink.

8.Do heatsinks impact motor efficiency?

Yes, efficient heat dissipation can lead to improved motor efficiency. By preventing overheating, heatsinks maintain consistent performance and reduce energy loss.

9.Can I customize the design of a motor heatsink?

Many manufacturers offer customization options for motor heatsinks. You can tailor the heatsink's size, shape, and material to meet your project's requirements.

10.Are there any installation considerations for motor heatsinks?

Proper installation is essential to ensure effective heat transfer. Follow the manufacturer's guidelines and ensure the heatsink has proper contact with the motor's hot components.

Tone offers a diverse range of motor heatsinks, available in various sizes, shapes, and surface treatments. We employ multiple manufacturing techniques including extrusion, bonded-fin, skived fin, and forging for Heatell motor heatsinks. Crafted from 100% aluminum materials, our motor heatsinks boast exceptional thermal conductivity.

Our motor heatsinks come with an array of surface treatment options such as anodizing, powder-coating, and mill-finish. If you prefer a naturally occurring oxide layer, our anodized motor heatsinks are a great choice. Anodization enhances wear resistance, corrosion resistance, surface emissivity, and electrical isolation.

Discover the added aesthetic dimension with our anodized motor heatsinks, available in colors like blue, green, black, red, and more. At Tone, customization is at the core of our service. You can tailor your motor heatsink to your desired surface treatment, manufacturing process, size, and specific requirements. Just share your detailed specifications, and we will precisely craft your ideal heatsinks.