custom vapor chamber

As a manufacturer, we specialize in custom vapor chamber solutions to meet the specific thermal management needs of our clients. Our custom vapor chambers are meticulously designed and engineered to efficiently dissipate heat from electronic devices. We work closely with our clients to understand their requirements and tailor our vapor chambers accordingly, taking into consideration factors such as device size, power density, and thermal performance objectives. Our team of skilled engineers and technicians utilize state-of-the-art technologies and advanced manufacturing processes to ensure the highest quality and performance of our custom vapor chambers. Whether it's for high-performance gaming PCs, data center servers, or advanced medical equipment, we take pride in delivering innovative and reliable vapor chamber solutions to help our clients achieve optimal thermal management and enhance the performance and reliability of their products.

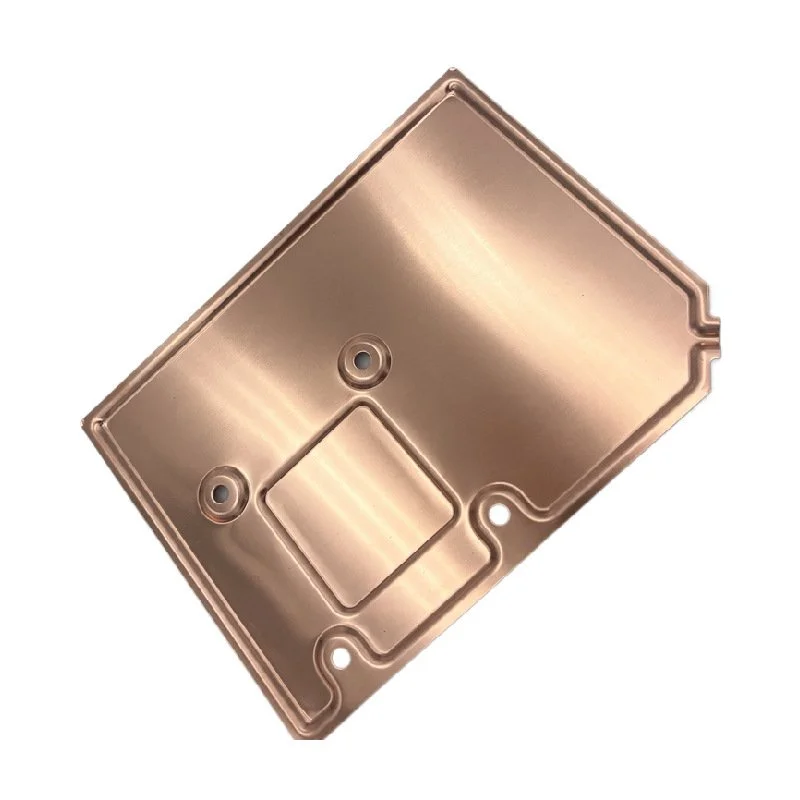

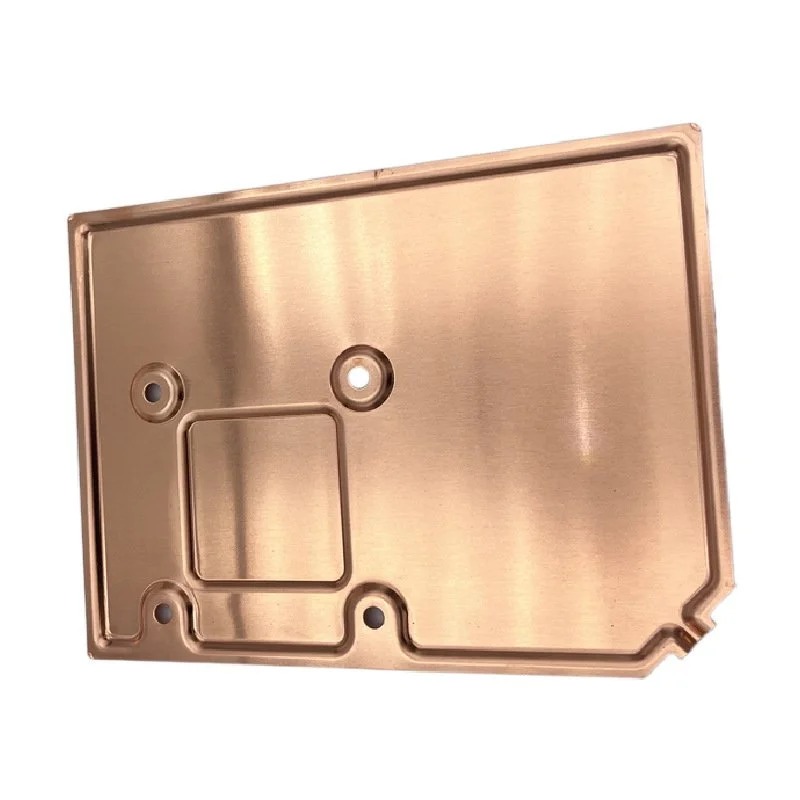

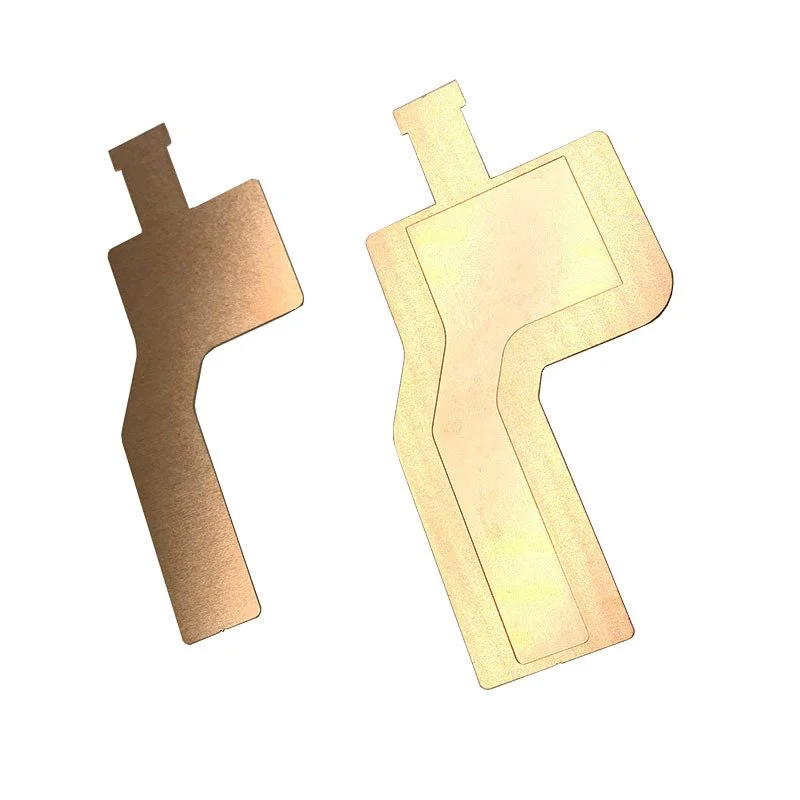

CONVENTIONAL VAPOR CHAMBER

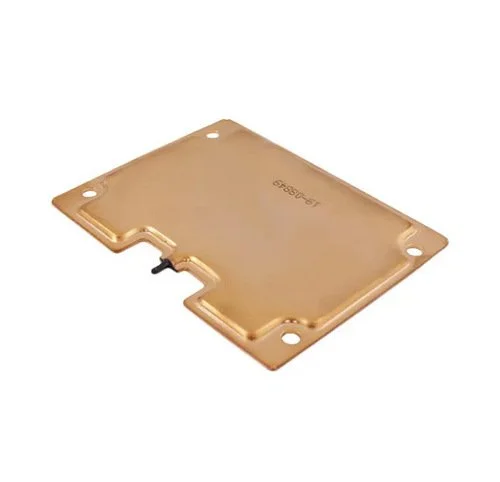

ULTRA-THIN VAPOR CHAMBER

STAINLESS STEEL VC

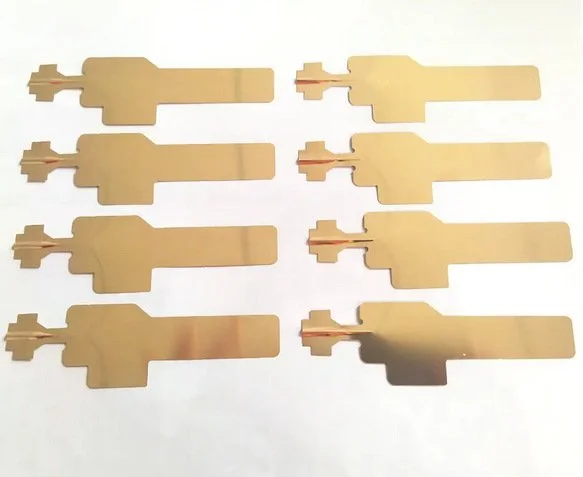

BLOW-UP BOARD

● High thermal conductivity

● Efficient heat spreading

● Space-saving design

●Versatility

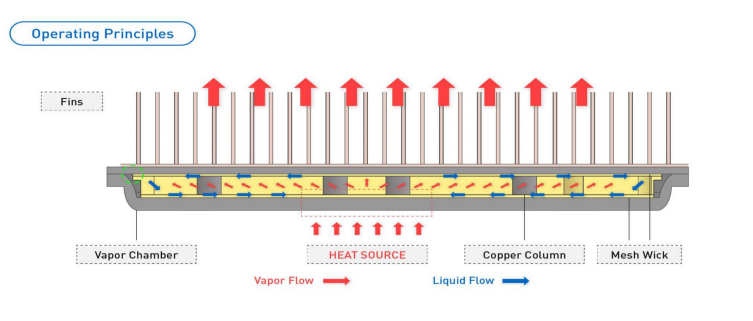

-Vacuum-sealed chamber with micro-structured

-liquid (water) as heat transfer medium.

-Heat transfer (evaporation & condensation) by two-phase change

VC Vapor Chamber Principles

Vapor chambers have a comparable power handling capacity to multiple heat pipes, ranging from a few watts to over a kilowatt. However, if the thermal and physical requirements can be met by a single heat pipe, it is usually more cost-effective to use them, considering post-production operations like machining. Therefore, the adoption of vapor chambers over heat pipes is typically seen in applications that involve higher power and/or higher power densities. For applications with lower power requirements, heat pipes may be sufficient.

Power Handling Capacity

Vapor chambers are especially suitable for cooling electronics in high power density applications, typically above 20 W/cm2 but below 500 W/cm2. In such situations, it is crucial to efficiently spread heat over a larger surface area.

Power Density Capacity

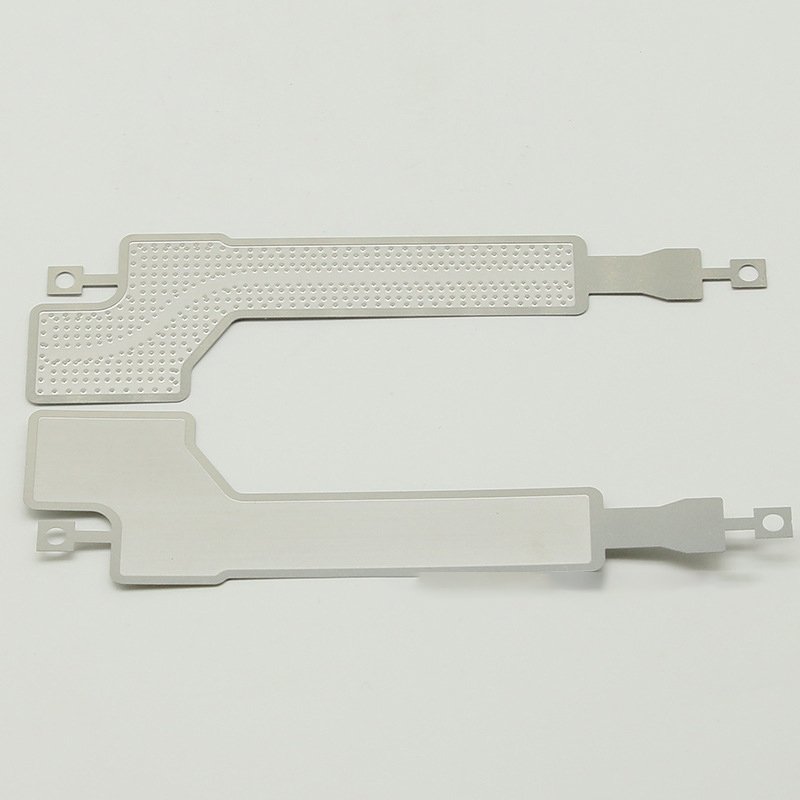

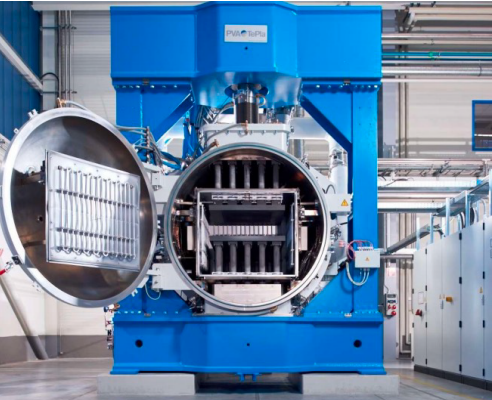

The traditional manufacturing process of vapor chambers involves two stamped plates, which are mirrored images of each other and eventually bonded together through diffusion bonding. This allows designers a great degree of flexibility in the X and Y dimensions. The maximum length and width dimensions depend on press and furnace sizes, as well as specific application requirements. As a result, vapor chambers larger than approximately 300 x 400mm are not commonly found.

Shapes & Dimensions

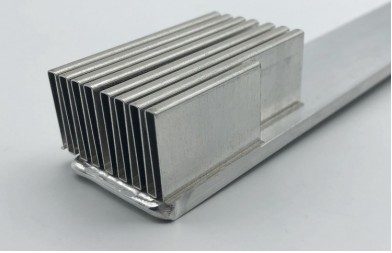

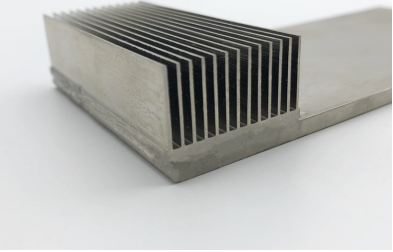

Vapor chambers can be attached to any type of heat sink (extruded, skived, etc), but they are typically paired with zipper fins or machined heat sinks. This is because both of these heat sink options offer excellent thermal performance. Zipper fins have very thin, closely spaced fins, while machined heat sinks have virtually infinite design options. In some cases, vapor chambers can also be successfully paired with die-cast housings that have integrated fins, particularly in extreme environments.

Vapor Chamber Heat Sink Integration

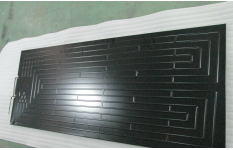

*Molecular diffusion welding is a welding process that does not require any solder. The principle is to use high temperature and high pressure. Let two or more need to weld together the metal, so that its metal molecules at high temperatures quickly active at the same time using ultra-high pressure, so that the elemental molecules between the metal quickly diffuse each other, so as to achieve the effect of combining with each other.

*Molecular diffusion welding is a high-level joining process, welding combined products with super stability has been the military, aerospace, rail transportation and other needs of high-level combination of process favourites.

*Our temperature plate upper and lower cover are combined with the diffusion bonding process for welding, so that the stability of its product performance is better than the industry, is the first to apply diffusion bonding in the mobile phone ultra-thin temperature plate of the enterprise diffusion bonding does not require any solder to assist in the welding, will not result in solder contamination of the product and the environment pollution and other conditions.

Mass production process features

Molecular Diffusion Bonding - The Most Solid Welding Process Available

Vapor chambers are advanced heat transfer solutions that offer several features and benefits. Here are some of the key features and benefits of vapor chambers:

Efficient Heat Spreading: Vapor chambers excel at spreading heat evenly across their surface, allowing for efficient heat transfer. This feature helps to prevent hotspots and ensures uniform temperatures across the heat source.

High Thermal Conductivity: Vapor chambers have excellent thermal conductivity, often surpassing that of traditional heat pipes and solid metal solutions. This means they can transport heat more effectively and efficiently.

Thin and Compact Design: Vapor chambers have a thin and flat design, making them ideal for applications where space is limited or a low profile is required. They can be easily integrated into compact electronic devices or confined spaces.

Reduced Thermal Resistance: Vapor chambers offer minimal thermal resistance between the heat source and the cooling solution, resulting in efficient heat dissipation and improved overall thermal performance.

Versatility and Customization: Vapor chambers can be designed and manufactured in various sizes, shapes, and configurations to fit specific applications and thermal requirements. The customization options allow for optimal heat management in a wide range of electronic devices.

Enhanced Cooling Performance: By utilizing a combination of phase change and heat conduction, vapor chambers can handle high power densities and efficiently dissipate significant amounts of heat. They are particularly beneficial for high-performance electronic devices and applications.

Reduced Weight and Cost: Vapor chambers are often lighter compared to traditional cooling solutions, such as heat sinks with heat pipes. This lightweight design contributes to their suitability for portable or mobile devices. Additionally, vapor chambers can help reduce costs by eliminating the need for multiple heat pipes or complex cooling systems.

Features & Benefits

A vapor chamber, also known as a flat heat pipe, utilizes two-phase cooling with high heat transfer capability in a flat format. In electronic cooling applications, where heat energy transfer occurs on a heat sink very close to the heat source, the use of a vapor chamber assembly is ideal for diffusing high heat density or heat load over a larger surface. Vapor chambers offer increased and more uniform heat dispersion, optimizing the performance of the heat sink. The use of vapor chambers has gained traction due to the significant increase in total power and resulting power density caused by reduced chip size. Today's vapor chambers are more capable and less costly, allowing for greater application flexibility and adoption.

Vapor Chambers

Custom-made goods

Self-developed products

325*315*6mm

260*210*4mm

180*130*2.5mm

165*58*1mm

140*80*4.5mm

61*60*5mm

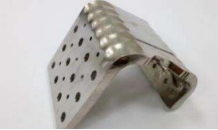

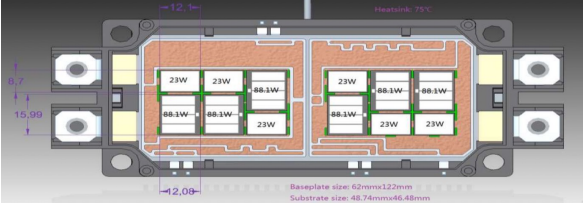

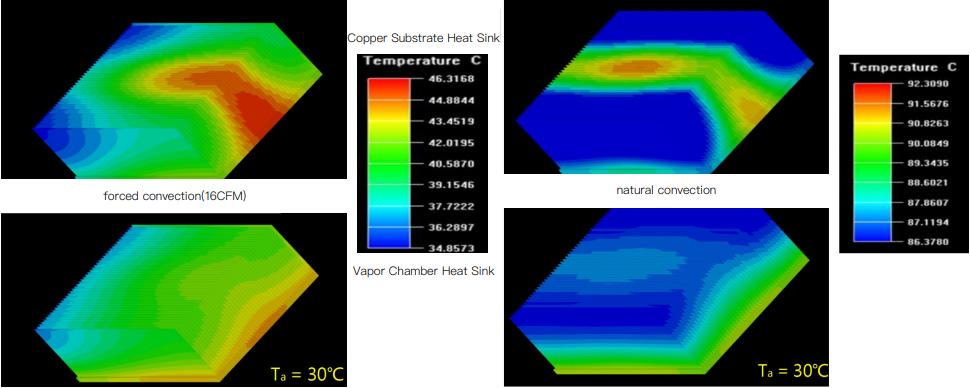

IGBT Cooling Applications: Vapor Chamber VS Copper Substrates

Total heat = 666.6w

Cooling water flow rate: 1L/min

Advantages

Fast lateral heat spreading characteristics to address hot spots

Better wing pian utilisation performance